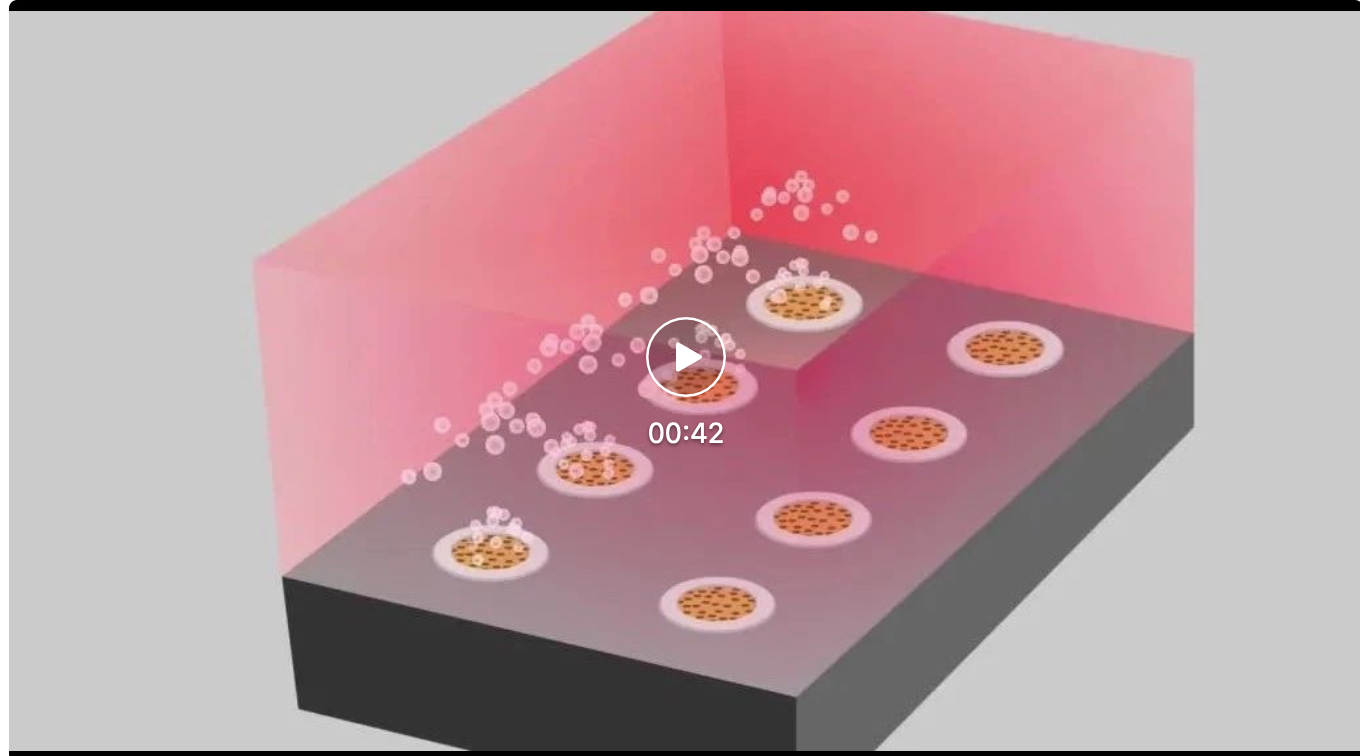

Bubble bed green melting equipment

he melting furnace bubble bed without flux developed by Fujian Metal-new adopts pure physical metallurgical method instead of chemical metallurgical method of flux refining, that is, without refining agent, the content of inclusions and gases in aluminum melt can be reduced to the current purification level of flux spray refining; The chemical composition uniformity of the melt in the furnace can be achieved by using gas wave stirring, which can ensure the quality of alloying and the purification effect of good purity. Certified by the National Non-ferrous Metal Industry Association, it has reached the international leading level. Has won the national non-ferrous metal science and technology progress award, has applied for invention patents.

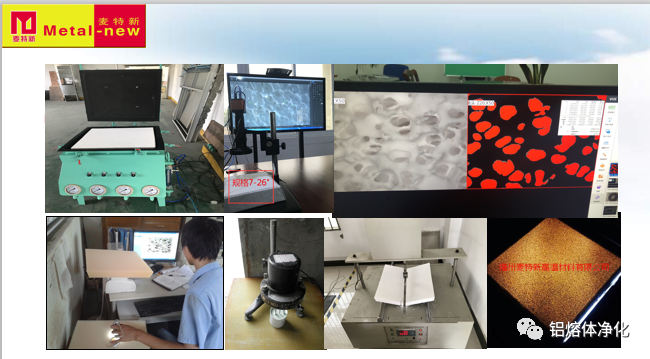

New Foam Ceramic Filter Plate (MTX-CFF)

The new structural material is the world's advanced low-temperature and clean sintering technology of the international cooperation between China and Russia (the world famous expert in chemistry and high-temperature materials, Academician Yuri Allesandrokov); China Innovation No. 2003CO12W, using three-dimensional network structure, is superior to honeycomb foam type, with high porosity, low filtration resistance, small normal static difference, high surface energy, strong impurity adsorption, excellent thermal shock resistance, high strength, no slag (ceramite) and other advantages. Widely used in the aluminum processing industry of aluminum melt filtration and purification, better improve the quality of aluminum, and expand the application in environmental protection engineering and heat energy utilization, catalytic carrier and other fields.

FMT slag tester

With the continuous development of aluminum processing, the application field of aluminum alloy is more and more wide. Aerospace aluminum, food packaging, automotive aluminum and other high-end aluminum products should strictly control the content of aluminum melt slag, especially the national standard "Aluminum and aluminum alloy ingot purity expression method" clearly puts forward the content control requirements of aluminum alloy slag. The detection and control of slag content in aluminum melt are becoming more and more important. Metxin specializes in the purification of aluminum alloy melt, and has cooperated with internationally renowned experts to develop FMT-3 aluminum alloy slag measuring instrument, which is mainly to record the time weight curve of aluminum melt through micron filter under isothermal and isobaric environment. Through the curve to judge the aluminum melt slag content range, and then through

Scientific research small melting casting experiment line

The main function of the degassing furnace is to keep heat after the melt flows into the degassing furnace. At the same time, the inert gas is dispersed into the aluminum melt through the rotating impeller, and after collision, capture, adsorption and partial pressure, the gas in the melt is brought out of the aluminum liquid surface with the gas floating up, so as to achieve the purpose of degassing.

What can we do for you

Wuhushan Industry Area, Qingkou Investment Zone, Fuzhou, Fujian, China

Follow us

Website

MESSAGE

扫描关注我们